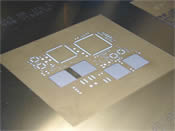

Step/Relief Stencils

Through the increase of mixed technologies, stepped stencils have gained importance to the electronic assembly manufacturer. If the solder paste quantity can no longer be adequately regulated by adjusting  the pad sizes, stepped stencils are necessary to optimally match the soldering paste volumes. Relief areas can be etched into the board side of the foil for use on rework boards. The higher reworked area fits into the relief etch allowing the stencil the lay flat on the SMT pads. This minimizes bridging by ensuring a gasket seal between the stencil and board pads. Damage to the board and stencil is also minimized. This is an excellent solution for boards with labels and boards with filled vias. Relief etches are chemically etched into the board side of the foil, yet all apertures are laser cut.

the pad sizes, stepped stencils are necessary to optimally match the soldering paste volumes. Relief areas can be etched into the board side of the foil for use on rework boards. The higher reworked area fits into the relief etch allowing the stencil the lay flat on the SMT pads. This minimizes bridging by ensuring a gasket seal between the stencil and board pads. Damage to the board and stencil is also minimized. This is an excellent solution for boards with labels and boards with filled vias. Relief etches are chemically etched into the board side of the foil, yet all apertures are laser cut.

Step stencils: Variable stencil thickness in specific areas to accommodate reduced volume (step down) or increased volume (step up). Used to control paste deposits on PCB’s having both standard pitch and fine pitch SMT as well as intrusive reflow/paste-in-hole components. Steps are chemically etched into the squeegee side of the foil, yet all apertures are laser cut.

Different design and layout specifications have to be taken into account in the manufacture of stepped stencils. Customer Service will be pleased to advise you.