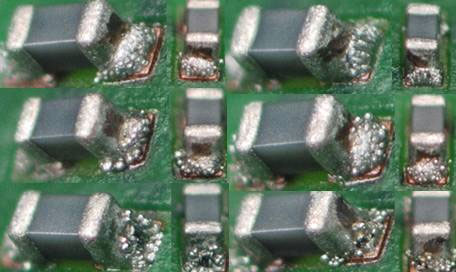

Graping Issues

Issue Description: Incomplete coalescence of solder powder into the joint. This defect has the appearance of a bunch of grapes.

1) Optimize the reflow profile to minimize oxidation of the solder powder and to maximize activity of the flux during reflow.

1) Optimize the reflow profile to minimize oxidation of the solder powder and to maximize activity of the flux during reflow.

Shorten soak time to reduce oxidation of the solder powder prior to reflow, and to prevent premature loss of flux activity.

Increase peak temperature to provide more heat for the solder powder to completely coalesce.

2) Use Type 3 solder powder rather than Type 4 or 5 if the application allows.

Type 3 solder powder has lower surface area and correspondinly lower oxide relative to Type 4 or 5 solder powders.

3) Switch to a higher activity solder paste formulation.

We supply higher activity versions of many of our solder pastes in order to combat these type of issues. The use of higher concentrations and different types of activators allows the paste flux to deal with high levels of oxide on solder powders.

WS889A8 is a higher activity version of WS889, NL932X and NL932PTX are higher activity versions of NL932 and NL930PT respectively.

4) Modify the stencil to print a higher volume of paste in trouble spots.

Graping is typically seen on smaller pads, where solder paste volume may be insufficient. Our NanoSlic stencil coating provides the benefit of increased solder paste volume even through apertures down to 0.300 SAR (surface area ratio).

Apertures can typically be enlarged resulting in higher solder paste volume.